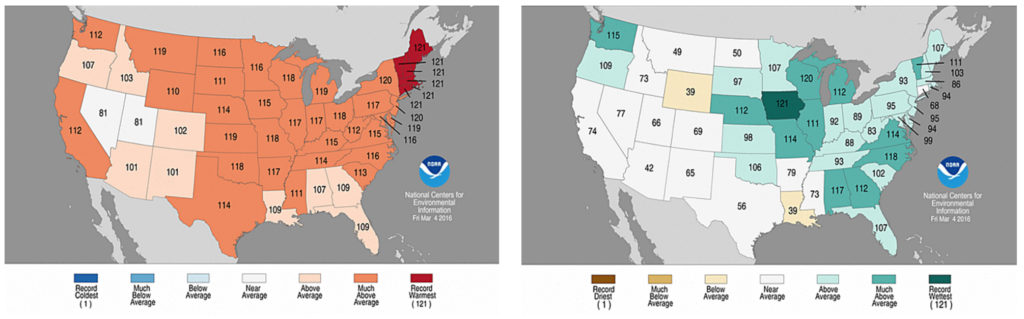

Many producers had a good application window for anhydrous ammonia applications this fall. Many of us unhooked from the applicator around Thanksgiving feeling good about our nitrogen plan. Then we had one of the warmest and wettest Decembers.

Statewide Average Ranks: 1895 – 2016

Dec ’15 – Feb ’16

Temp – ? – ? – ? – ? – ? – ? – ? – ? – ? – ? – ? – ? – ? – ? Precipitation

Data: NOAA nClimDiv

Two bad things happen to ammonia in warm and wet conditions. First, ammonia quickly converts to ammonium, which is a stable form of nitrogen. But in warm conditions, nitrosomonas bacteria are active in converting NH4 to nitrite and then nitrate. Nitrates move with moisture. So those drenching December rains were expensive events – moving too much expensive nitrogen deep into the soil profile. Inhibitors like N-Serve, destroy the nitrosomonas bacteria to slow the conversion to nitrite. In normal conditions, inhibitors extend the conversion window by eight to ten weeks. Plus, standing water, temps above 50o and a lack of oxygen in the soil drives denitrification.

So how much loss has occurred with this double December whammy of heat and moisture? In tests done by 360 Yield Center, we’ve seen significant amounts of ammonia convert to the more risky nitrate form in just 60 days. A November 5 application of 110 units of NH3 (with N-serve) showed that by early January, as much as 33% of the applied nitrogen was in the nitrate form (not including the carryover and mineralized soil nitrates). That means one third of the nitrogen investment was at at strong risk of moving out of the root zone between January and corn emergence in May.

A Climate Insights article (http://www.climateinsights.com/managing-nitrogen-during-a-warm-wet-winter/) summarizes tests where 25 to 95 pounds of the 200 applied pounds of nitrogen had moved below the top two feet of soil.

Weather patterns force us to evaluate our nitrogen supply. Corn will use three quarters of the nitrogen it needs after V10 – seven months after fall applications. How many more two-inch rains will we have between now and V10? No one knows. We do know that in 2015, heavy rains flushed the majority of our nitrates out of the root zone. And we already know that we have a faster-than-normal conversion to susceptible nitrate. We should make plans now to protect our yield potential by insuring we have a plan to measure and resupply nitrogen.

Measure to understand nitrate availability

It is never too early measure nitrate levels. By testing at planting and bi-weekly through pollination, you can generate a nitrate map. This map can indicate ammonium-to-nitrate conversion rates and pinpoint how much mineralization is taking place. 360 SOILSCAN TM, the in-field nitrate and pH testing tool provides a quick and inexpensive way to perform these frequent tests. The device’s N Needs Calculator indicates the amount of additional nitrogen, if any, needed to finish the crop to meet your yield goals.

Plan now for supplemental nitrogen application

With the risk of early conversion, producers are adjusting their cropping plan to include additional nitrogen with the planter, at side dress or with a mid-season application. 360 Yield Center’s 2015 field trials showed a consistent response when soils were tested to determine application rates, followed by an application after V9.

There may be high demand for your ag retailer’s sidedress bars this spring so plan ahead to secure a source for mid-season application. 360 Yield Center has a custom applicator locator that helps growers find application services – https://www.360yieldcenter.com/where-to-find/.

A base plus approach reduces risk

360 Yield Center recommends a split application strategy to maximize nitrogen availability and efficiency. Supply enough nitrogen via fall, pre-plant or at-plant applications to ensure an adequate supply to reach V8 to V10. Then measure the nitrate levels at various locations in each field to determine your application rate. Finally, as late in the growth cycle as possible – based on weather and your applicator’s clearance – apply UAN at the base of the plant for rapid uptake over the root mass.

Nitrogen is one of our most expensive inputs. It has a strong correlation to yield. And it is one of the most mysterious inputs to control. New measurement and application tools help us supply what the corn plant needs, when the corn plant needs it.

N-Serve is a registered trademark of Dow AgroSciences