Managing nitrogen costs is critical to achieving profitable corn production. Even in today’s cheaper N environment, there is simply no room for inefficient application of this vital crop input. Traditionally, we used the “1.1” formula. We were told to apply 1.1 pounds of N for each bushel of corn we expected to raise. But as…

Where’s My Nitrogen? How To Make A ‘Nitrogen Map’

Many growers apply nitrogen in the fall to take advantage of the wide application window. But there are risks with fall application. Applying seven months prior to planting leaves nitrogen vulnerable to loss from rain events and warm winters. Because nitrates easily move in the soil profile, it is important to map that movement to…

Evaluate Your Residue Management: 4 Characteristics of a Quality Seed Bed

The success of your seed bed started with your combine pass last fall. Managing residue and compaction in the fall sets the stage for the 2017 seed bed. A quality seed environment requires four things: Uniform depth Uniform moisture Uniform temperature Seed to soil contact Uniform depth Consistent depth means consistent emergence. One collar delay…

Don't Tie Up Your Nitrogen: 3 Tips for Managing the Carbon Penalty

When the soil warms up in spring, the microbial organisms that break down the previous season’s corn stalks use nitrogen as a food source. When those organisms are busy breaking down the corn stalks, they tie up nitrogen that would otherwise be available in your fields for plant use. The tie up is often called…

Where is My Nitrogen? The Positives and Negatives of Anhydrous

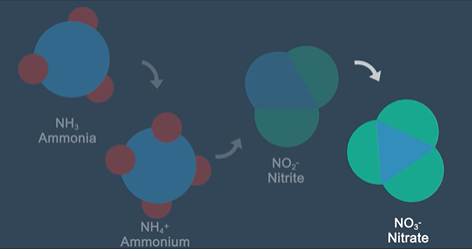

Nitrogen moves in the soil profile because of environmental factors – precipitation, temperature, etc. – but it’s important to understand the chemical process happening behind that movement in order to better control it. Let’s start by reviewing the transformation of one form, Anhydrous Ammonia. It enters the soil ammonia (NH3). It quickly grabs a hydrogen…

TRIAL DATA: Placement Boosts Nitrogen Uptake And Yield

A corn plant takes up most of its nitrogen from a 7-inch radius. Improving placement by banding nitrogen fertilizer along the base of the plant leads to improve uptake. In 2016, 360 Yield Center partnered with the University of Illinois using a tracer ion in a nitrogen solution called 15N to compare uptake efficiencies from…

Benefits of Converting Your Bar to 360 Y-DROP Sidedress

This year, as you prepare for side dress season, consider converting your bar to 360 Y-DROP Sidedress. There are numerous reasons why 360 Y-DROP Sidedress is an effective and efficient choice for side dress application. Optimized placement of nitrogen is the biggest draw of the 360 Y-DROP Sidedress system. Studies have shown that a corn…

360 EQUI-FLOW now available with Variable Orifice Manifold

Morton, Ill., February 23, 2017 – 360 Yield Center unveils a Variable Orifice Manifold for the 360 EQUI-FLOW anhydrous applicator. The manifold allows operators to vary NH3 application rates to match the variablitliy of soil types, slopes and organic matter. It works in conjunction with 360 EQUI-FLOW, a pressurized application system that increases row-to-row accuracy…

A to Z of Crop Nutrients: Zinc (Zn)

As we continue to examine the micronutrients, let’s focus on Zinc. Zinc performs multiple functions in a corn plant. It is important in many enzymatic reactions and protein synthesis, and can also impact hormone production which affects growth and can cause shortened or stacked nodes. In corn, interveinal chlorosis in young tissue can be a…

360 YIELD SAVER Added to Agreement with John Deere

Morton, Ill., Feb. 14, 2017 – 360 Yield Center has expanded its allied agreement with John Deere to include 360 YIELD SAVER™ for use on the John Deere 90 series and 600C/FC series corn heads. By including 360 YIELD SAVER in the distribution agreement, Deere approves the use of the product on its machines. The…